询价热线:18662833666

询价热线:18662833666性能特点:

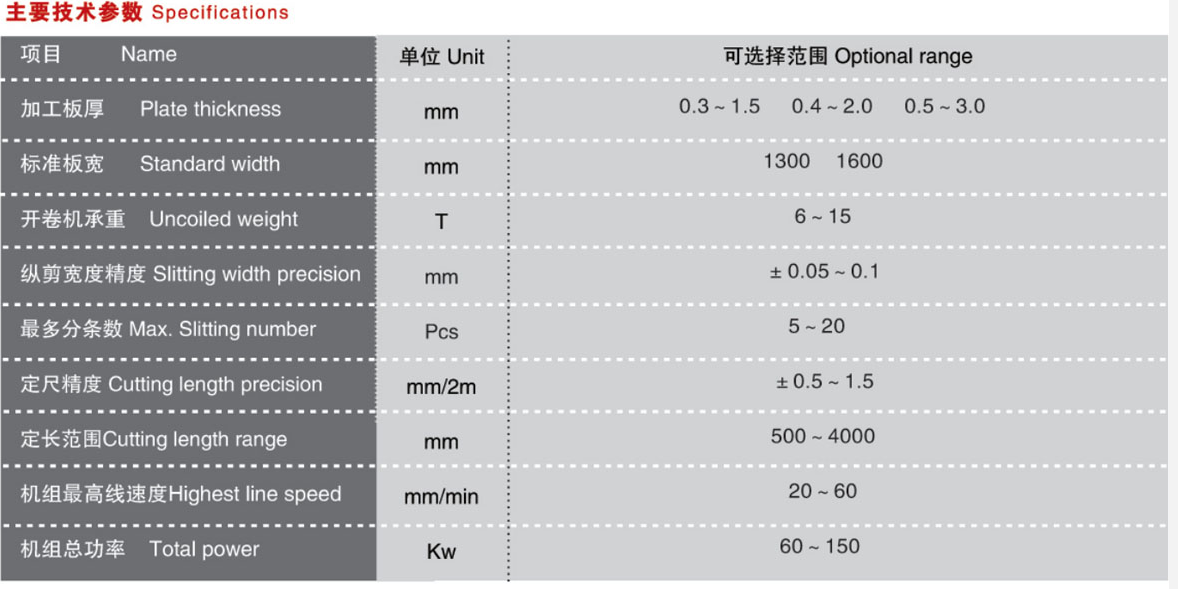

本设备用于不锈钢、镀锌板、冷轧板卷料的开卷、校平、剪切、收卷作业,自动程度高、生产效率高。全线电 气控制整机联动,加工精度高。整条生产线机械、电气、液压、气动自动化控制一体化,从开卷、校平、纵剪、 横剪、收卷实行同步控制。整套设备考虑到所加工材料的表面要求较高,设计的各种过桥托辊输送装置,表面采 用特殊工艺,不会造成板料压痕、碰伤、划伤、折边、咬边等现象。

Features:

This line is for uncoiling, leveling, slitting, cut-to-length, recoil of stainless steel, galvanized sheet and cold coils. High automatic working and efficiency, the whole line linked-control by electric, high processing precision. And whole line integrated of mechanical, electrical, hydraulic, pneumatic control, synchronized uncoiling, leveling, slitting, cross-cutting and recoiling. By consider of high surface request, the designed bridges* support roller transport device, all surface adopt special art, will not occur indentation, bumps, scratches, folding and undercut.